Such so-called structural colors are more durable than colors of pigment or dye, the researchers wrote in the magazine this week Science Advances. The transparent ink with which the balls are made can easily be recycled and the colors last much longer.

Trying to imitate nature

Such structural colors are common in nature, for example in peacock feathers. And with morphos (those bright blue butterflies). They do not owe their color to pigment, but to scales on the wings. The microscopic structure of the scales only reflects the blue light.

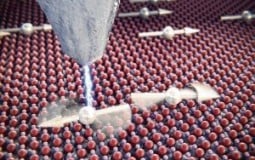

For some time now, scientists have been trying to imitate nature: to print structural colors. Instead of using drops of pigment ink or chemical dye, they create the colors by printing a microscopic 3D structure (like those on the scales of the morpho) of different materials on a flat surface. But that’s not easy. Some structural colors are printed outside the lab, but a detailed combination of different shades in one image was complicated to print with a simple inkjet printer.

Tiny colorless spheres

So now the Chinese scientists found a way to do that. They first calculated which physical structures reflect which colours. With that information, a computer translates the digital image, in the case of a portrait of Isaac Newton, into a structure made up of miniscule colorless spheres with different diameters and shapes. A combination of different diameters and shapes determines the color of an area.

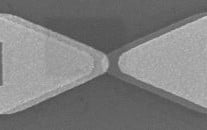

When the bubble design is ready, the computer commands a converted inkjet printer to print it. In that printer, the temperature is kept at approximately twenty-five degrees Celsius to prevent the bubbles at the edges from evaporating. All spheres are made with one colorless ink. The printer sprays the ink onto hydrophobic glass so that the drops of ink on it contract into spheres. The printed portrait is colored on the flat side and transparent on the other side (the dotted side).

Fantasizing about applications

“Wonderful,” Albert Schenning calls the study over the phone. He is professor of smart materials at Eindhoven University of Technology, not involved in the study and is already fantasizing about applications. “For example, smart windows that only reflect infrared light.” That is a color that cannot be seen with the naked eye, but feels like warmth.

Jo Geraedts, professor at Delft University of Technology and also not involved in the study, is more reserved. He calls two bugs that have yet to be resolved. “The first is that the color range of the researchers is limited. To make more different shades, you need smaller balls. But with even smaller spheres, the amount of ink is so small that it flies off into the air before it hits the glass.” The second problem he mentions is that deep black is missing in the researchers’ printer. Brownish black can still be made by mixing colors, “but a separate pigment ink is needed for deep blacks,” notes Geraedts.

Structural colors do not suffer from fading

Why do the researchers want to print with structures at all if it is already possible with pigment or dye? “First, structural colors last longer,” says Schenning. “Pigment and dye fade over time. As it absorbs light, pigment or dye decomposes and reacts with the air and fades. Structural colors do not suffer from this. Even the structural colors of some fossils have remained intact.”

The transparent ink is also easily recyclable, says Schenning: “With a mixture of ink and pigment, the pigment must first be separated and that is a hell of a job. Pigment ink is thrown away and is plastic waste.” Geraedts calls this comparing apples to oranges. “It is not the case that the converted printer can replace the normal printer that prints on paper. The method of the Chinese researchers does not work with paper. Paper is not hydrophobic and the substrate must reflect well.”